Services

Design thinking

to accelerate

At Flex/design, we merge creativity with technical expertise to drive meaningful change. With the principles of design thinking at our core, we created a rich set of services to help you make more impact in each phase.

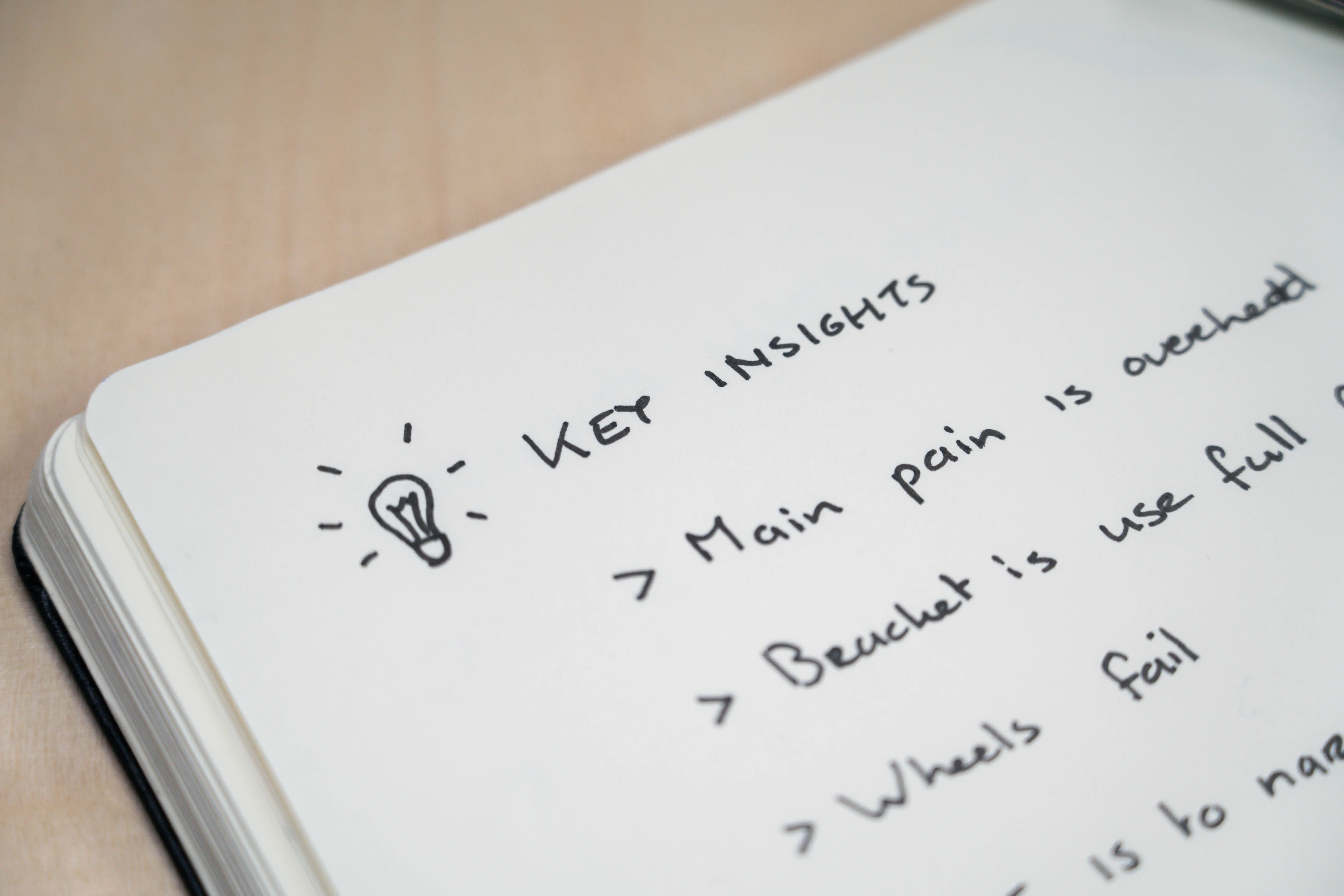

Discover

Together we define the project’s scope, assess potential impact, and have a look at competition and market. Services linked to this phase aim to turn abstract information into ideas which can be further explored in the design phase. insights into creative directions.

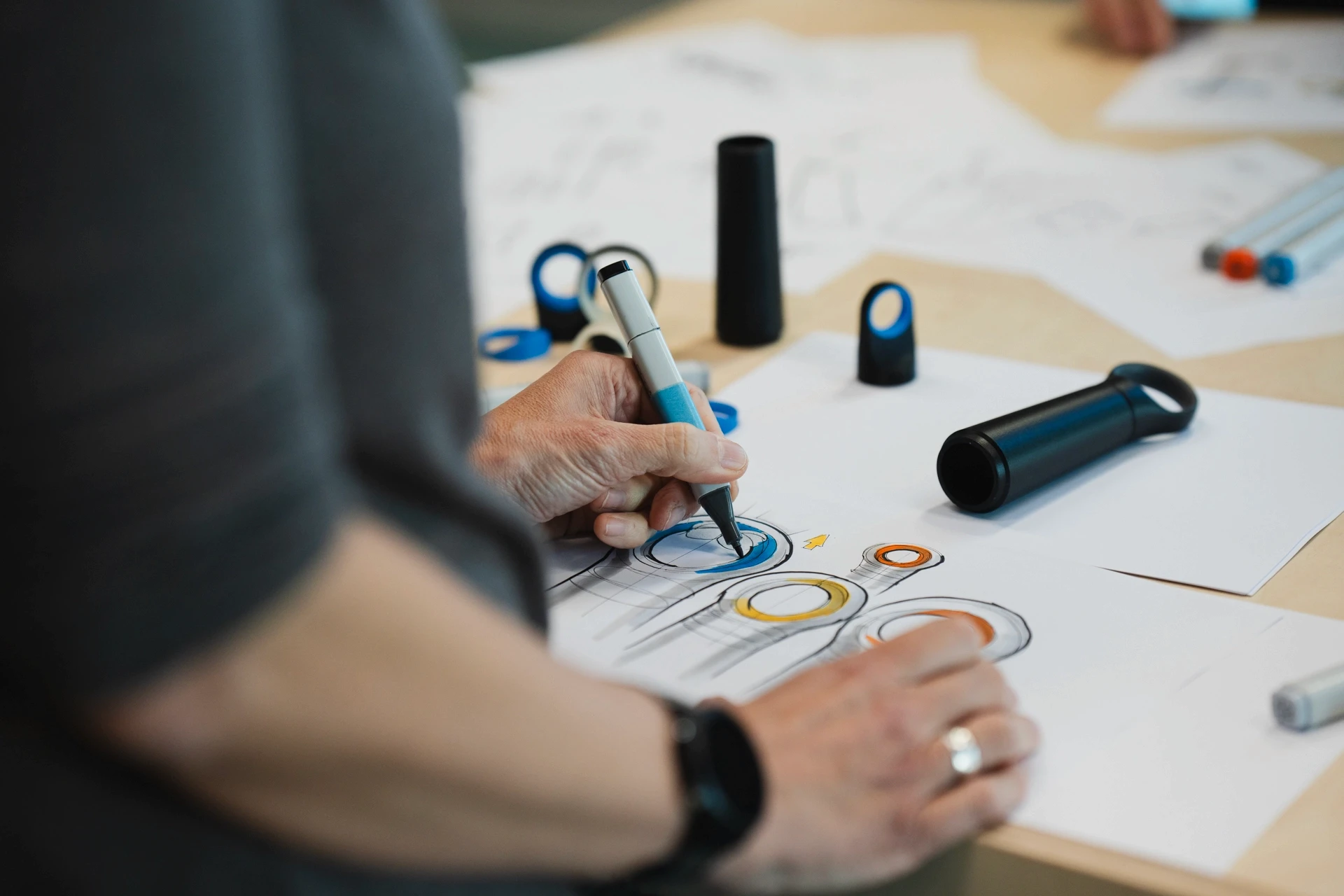

Design

In this phase, we explore and validate concepts with a focus on form, function, and feasibility. Services here bring ideas to life through prototyping, guiding stakeholders toward a refined vision for detailing in the next phase.

Deliver

We translate concepts into detailed, production-ready designs. This phase includes rigorous engineering, testing, and optimization, ensuring that each solution is prepared for scalable and reliable manufacturing.

Partnerships

While we have extensive in-house capabilities, we also collaborate with leading organisations to extend our expertise and resources.

"Everyday we see the impact of design thinking in our projects. Our clients are happy about the quick progress and have more grip on their complex innovation challenges."

Robin Hoenderdos

Creative Director

FLEX/design

"Everyday we see the impact of design thinking in our projects. Our clients are happy about the quick progress and have more grip on their complex innovation challenges."

Robin Hoenderdos

Creative Director

FLEX/design

"Everyday we see the impact of design thinking in our projects. Our clients are happy about the quick progress and have more grip on their complex innovation challenges."

Robin Hoenderdos

Creative Director

FLEX/design

"Everyday we see the impact of design thinking in our projects. Our clients are happy about the quick progress and have more grip on their complex innovation challenges."

Robin Hoenderdos

Creative Director

FLEX/design