With a range of Rapid Prototyping machines we can make the models you require, and we can make them fast. With our 3D printers we can make almost every model quickly and accurately.

There’s a variety of choices in plastics; transparent, flexible or for example with a wooden appearance.

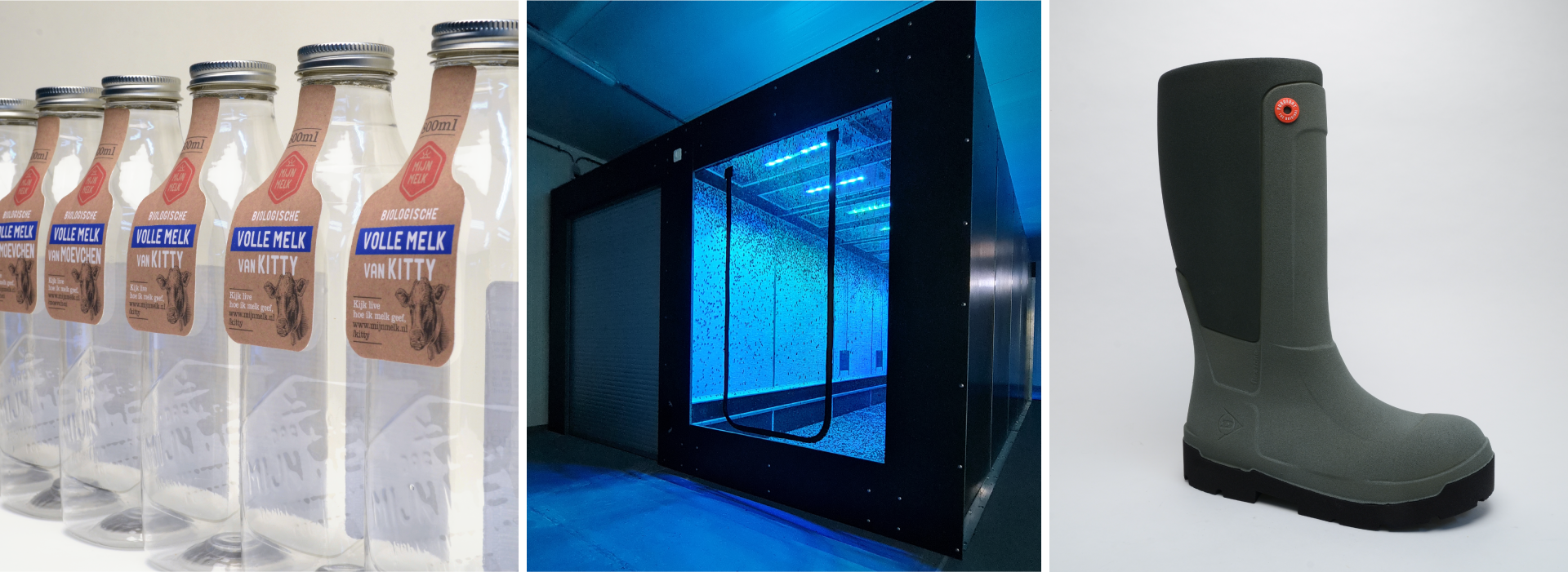

We make incredibly lifelike models and prototypes by using ‘traditional’ model making techniques as well as Rapid Prototyping. Using an array of specialized spray painting skills we’re able to achieve textured or transparent finishes. The prototype will look exactly like the desired finished product will look.

With a range of Rapid Prototyping machines we can make the models you require, and we can make them fast. With our 3D printers we can make almost every model quickly and accurately.

There’s a variety of choices in plastics; transparent, flexible or for example with a wooden appearance.

We make incredibly lifelike models and prototypes by using ‘traditional’ model making techniques as well as Rapid Prototyping. Using an array of specialized spray painting skills we’re able to achieve textured or transparent finishes. The prototype will look exactly like the desired finished product will look.

We take care of manufacturing small series of products using a wide range of techniques, like thermoforming, cardboard cutting and RIM-moulding, where plastic is injected using low pressure.

Blow moulding is also a service we provide for making high quality prototypes of PET-bottles with a very low investment needed.

A realistically looking model of the packaging will help in testing or presenting your product. Using our professional cutter plotter we will to make models of your cardboard packaging accurately and quickly.

Additionally, we use our thermoforming equipment to make blisters or trays to complement the cardboard pack.

We take care of manufacturing small series of products using a wide range of techniques, like thermoforming, cardboard cutting and RIM-moulding, where plastic is injected using low pressure.

Blow moulding is also a service we provide for making high quality prototypes of PET-bottles with a very low investment needed.

A realistically looking model of the packaging will help in testing or presenting your product. Using our professional cutter plotter we will to make models of your cardboard packaging accurately and quickly.

Additionally, we use our thermoforming equipment to make blisters or trays to complement the cardboard pack.

When making models and prototypes our skilled professionals use traditional as well as modern techniques, such as 3D-printing, milling, turning, RIM-moulding, wood- and metal working, vacuum forming, finishing and cardboard cutting. Our standards are exceptionally high; we evaluate and improve our processes constantly, leading to the completion of a large amount of very successful projects.

The translation form design into prototype comes as a second nature to Ron Noordhoek and Niels Molenaar. Combined, this enthusiastic team has more than 35 years of experience making models and prototypes. Traditional techniques as well as modern technology go hand in hand. Close cooperation with the designers and engineers at FLEX/design gives us great insight in the needs and demands of designers.

When making models and prototypes our skilled professionals use traditional as well as modern techniques, such as 3D-printing, milling, turning, RIM-moulding, wood- and metal working, vacuum forming, finishing and cardboard cutting. Our standards are exceptionally high; we evaluate and improve our processes constantly, leading to the completion of a large amount of very successful projects.

The translation form design into prototype comes as a second nature to Ron Noordhoek and Niels Molenaar. Combined, this enthusiastic team has more than 35 years of experience making models and prototypes. Traditional techniques as well as modern technology go hand in hand. Close cooperation with the designers and engineers at FLEX/design gives us great insight in the needs and demands of designers.

For Lely we build a scale model (M 1:10) of a new wind turbine design. The lifelike model has a height of 3 meters and is collapsible for easy transportion. The blades rotate automatically and even a small red LED light blinks at the top!

We just finished another series of room boxes for Saia-Burgess.

Saia-Burgess Benelux has been selected by Swisscom SHS and CitizenM hotels as technology partner for smart room controls for which these room box needed.

To better reflect the scope of the value we create, we felt it was time for a new name: say hello to FLEX/prototyping!

We always welcome questions, inquiries, remarks or ideas. Please don’t hesitate to contact us.

+31 (0) 15 214 34 98

design@flex.nl

FLEX/prototyping

Elektronicaweg 24

2628 XG Delft

The Netherlands