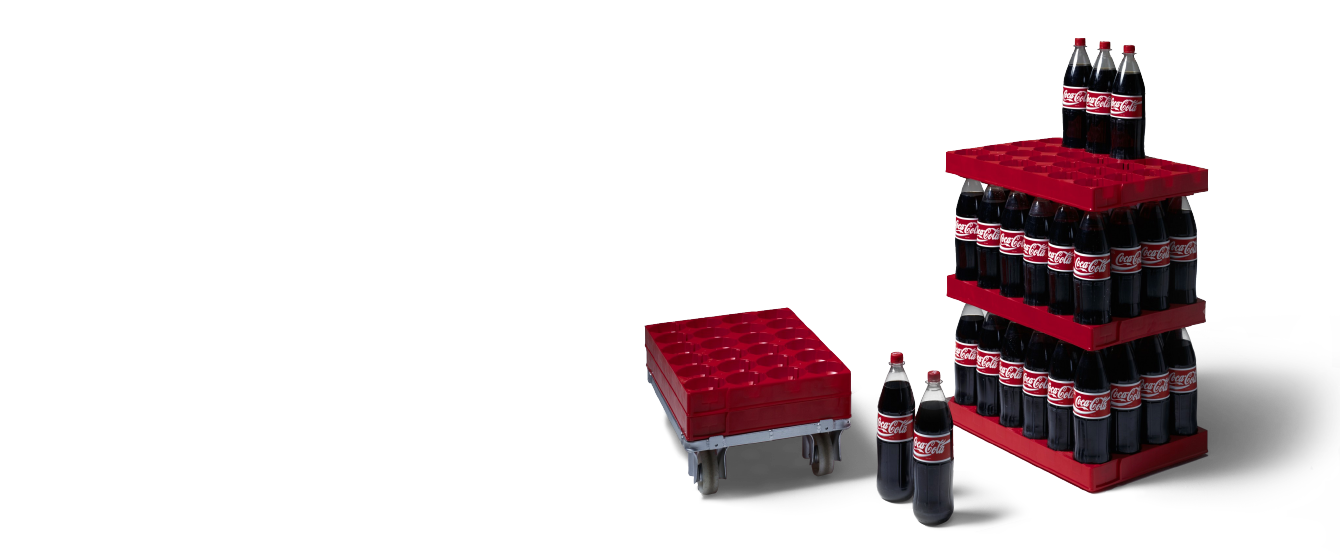

We developed a very efficient way to get 1,5L bottles from the production facility to the supermarket without all the handling cost in the logistic chain.

Dutch retailer Albert Heijn and Coca-Cola invited us to cooperate in the ESSO project; the development of an Efficient Soft drink Supply Outer. The company was suffering serious losses in the sales of soft drinks; and especially with so called ‘fast movers’.

The main cause was the labor-intensive character of the handling of the bottles from production until the shelf delivery, including the return-cycle of empty bottles and crates to the factory.

Inspired by packaging for eggs we developed a totally new logistic concept. A system that doesn’t require individual handling of crates and bottles until the consumer buys a Coke. The new solution also requires less material than excising crates.

Besides coming up with the ‘creative spark’, we were also responsible for the engineering of the tray, ensuring structural integrity, manufacturability and stability during transportation.

Dutch retailer Albert Heijn and Coca-Cola invited us to cooperate in the ESSO project; the development of an Efficient Soft drink Supply Outer. The company was suffering serious losses in the sales of soft drinks; and especially with so called ‘fast movers’.

The main cause was the labor-intensive character of the handling of the bottles from production until the shelf delivery, including the return-cycle of empty bottles and crates to the factory.

Inspired by packaging for eggs we developed a totally new logistic concept. A system that doesn’t require individual handling of crates and bottles until the consumer buys a Coke. The new solution also requires less material than excising crates.

Besides coming up with the ‘creative spark’, we were also responsible for the engineering of the tray, ensuring structural integrity, manufacturability and stability during transportation.

This case discussed in more detail in the thesis Creative Reflexion by Jeroen Verbrugge.

You can order a copy of the book here.

The new system is a big cost saver for Albert Heijn. They reduced overall labor costs related to the 1,5 liter Coca-Cola fast movers by approximately 15 million euro a year. Compared with the previous situation the reduction in material resulted in direct cost savings of over 1 million euro.

Because of the great potential savings Albert Heijn decided to use the system also for other brands. The system became the new industry standard for 1,5 liter PET bottles.