It’s safe to predict the automotive industry will change dramatically in the coming years as electric cars take over the market. This will have major implications for all the stakeholders in the industry. What will happen to the pertrol stations for instance, as people will mainly charge their car at home and at work? Red Bull – who’s been closely cooperating with the petrol sector for years – decided to gather a team of experts to find answers to this question.

Together with TNS, Instinct Laboratory, Wyne Strategy and Red Bull’s Out of Home team, we developed a toolkit for petrol station entrepreneurs to help them drive traffic to their location, after the main reason to visit – fuelling – has ceased to exist.

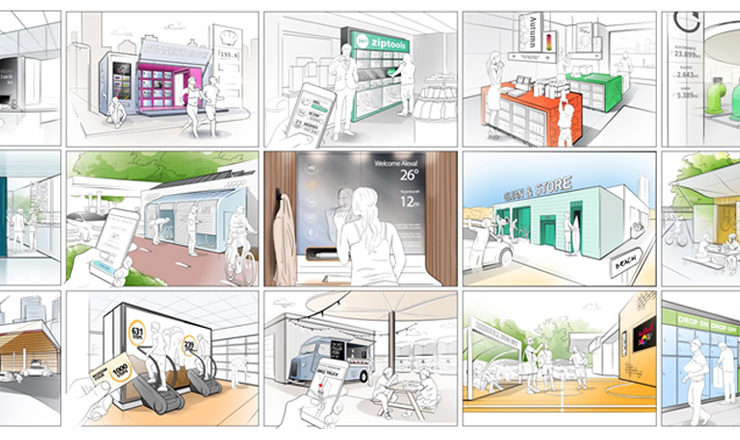

In this toolkit, the petrol station owners find concepts on the cross section of retail design, experience design and service design. Concepts that build on the specific characteristics of locations, as every location is unique when it comes to its surroundings, demographic profile, nearby retail, traffic situation and governmental plans.

These concepts were developed in the co-creation workshops we organized. In these sessions, we combined location characteristics with the extensive trend research done by TNS and Instinct Laboratory to come up with a large number of ideas. We thought about new categories that can be added to existing shops, but also about complete new destinations that offer people relevant reasons to visit a specific location.

The result: 15 modular concepts that re-invent stations’ value. Inspiring module examples: Module Runner’s Block – that facilitates running straight after work, DropOn/DropOff – a concierge service for all your small errands, Power Meeting – a room for super-efficient meetings, Dug out – to gather with your team mates before a game.

Red Bull aims to implement the first Future Station concepts still this year.