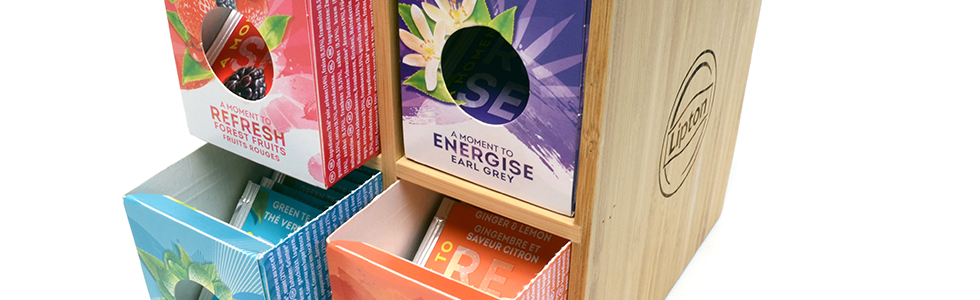

For Unilever’s Lipton Tea we created a dispenser holding four varieties of their Feel Good Selection. The dispenser radiates their brand story to take care of your spiritual wellbeing and enjoy a moment for yourself in a busy schedule, to energize, refresh, relax or get in balance. The use of Bamboo ensures a warm and natural appearance and is an environmentally friendly material. Together with the hot-branding on each side, it blends in perfectly with the graphic design of the boxes, strengthening Lipton Tea’s brand experience.

Unique feature: we made tea bags’ packaging part of the dispensing unit. Just open the top lit of the packaging, and the box becomes a drawer holding the tea bags. Our design solution is saving the use of material and is quite user-friendly.

“The brand team was very enthusiastic about your design! A fantastic achievement. A job well done! You have shown to be true packaging design experts” Pablo Groglopo – Sr. Design Project Leader at Unilever